Would you like to make this site your homepage? It's fast and easy...

Yes, Please make this my home page!

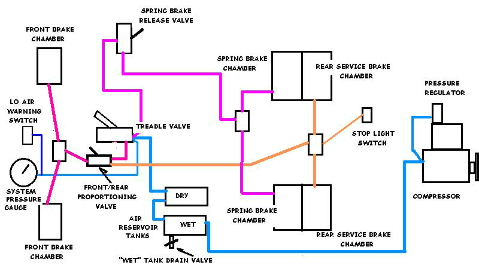

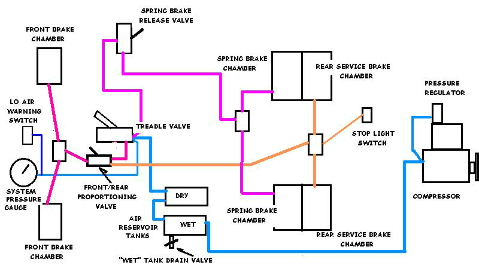

The Clipper Air Brake System

A. Overview

Although the evolution of the Air Brake System for heavy vehicles

involved a number of "refinements" over the years, the Bendix system as

used in the Flxible Clippers retained its simplicity during the

production of these coaches.

Schematic

Of The Clipper Air Brake System - Click To Enlarge |

Thus there are no "relay valves," or even

Spring Brakes, although the addition of the latter, being inexpensive

and easy to do, provides an extra margin of safey that is undeniable.

If your coach has not yet had this vital improvement added, it should be

done before you go anywhere. |

The basic elements of the system are these:

- 1. The Compressor - this is the heart of the system. Mounted on

the engine, it is driven from the engine's accessory drive - by a belt or

gears, and provides the compressed air necessary to operate the system.

The compressor is lubricated by pressurized oil fed by a line from the

engine's oil gallery, which drains back into the oilpan through a drain

line provided for this purpose.

- 2. The Pressure Regulator - this essential part of the system is mounted

on the compressor. It senses the system pressure, and engages or

disengages the compressor's function by temporarily disabling the valving. It

engages the compressor when the system pressure reaches a lower limit -

about 80 psi - and disengages it at the upper limit - about 120 psi.

The system reaching more than the upper limit could result in serious

damage to equipment and possibly personnel. When the compressor is

rendered "non-operational" by the regulator, it is still engaged and

turning; it just doesn't add to the system pressure until re-activated.

- 3. The Reservoir - this consists of a pair of air tanks - the

first in line designated the "wet" tank, the next the "dry" tank. The

"wet" tank provides, as well as air storage, a place for accumulation of

the condensation of

water produced by the compression and subsequent cooling of the air from

the compressor, as well as for the inevitable addition of some oil which

gets past the latter's piston rings. This tank must be drained of its

accumulated water/oil every day of operation. There is a drain valve

provided on the bottom of the tank for this purpose. Your dual-tank

reservoir system is located under the coach just ahead of the left rear

wheel. Condensation water tends to develop especially in cold

conditions - and it can make for real problems in freezing conditions!

- 3. (b) The "Blow-Off" Valve - As well as too little pressure, a

danger exists from the development of Too Much pressure. Thus the

installation of this spring-loaded check valve, mounted on the wet tank,

designed to release excess pressure in the case of the regulator not

cutting out when the maximum safe system pressure is reached - about 130

psi. In the case of a stuck (or frozen) regulator, severe system damage

could otherwise result. In your monitoring of your dashboard gauge, you

should also ensure that the pressure doesn't build up over into

the red zone. If the regulator is not cutting out, "fanning" the brake

pedal until you can safely stop and check your regulator is a great

idea!

- 4. The Lines - there is a system of lines and pipes connecting

the various components together. In the Clippers, this was done with

soft (bendable, or semi-rigid) copper tubing, although the modern

applications use special air-brake spec plastic tubing and connectors.

- 5. The Treadle Valve - the "brake pedal" operates this valve,

which directs air from the "dry" reservoir tank to the brake chambers,

located at the wheels. This valve is also a pressure regulator -

the greater the pedal movement, the more pressure is directed to the

brake chambers, and consequently the greater the braking power. This

results in a different "feel" to the brake pedal - with conventional

hydraulic brakes, there is a "feedback" provided by pressure felt with

the foot, although there is little relation between pedal movement and

application pressure. With Air Brakes, however, there is little

difference in feedback pressure - the degree of movement, or "how

straight is your ankle?" is the only indication of just how much braking

power is being applied

- 6. The Front/Rear Differential Valve - This is a distribution valve,

which regulates the relativity of the pressure being directed to the

front and rear brakes. In slippery conditions, you want less braking on

the front steering wheels than on the rears, since as the fronts approach

"lock-up," the steering goes away. For these conditions, the pressure

differential may be adjusted from the driving position - it will be

found located on the floor just ahead and to the right of the driver's

seat. (Below your right thigh.) Moving the

lever toward the rear takes some of the pressure off the

front brakes. In normal conditions (good traction), this lever

should be toward the front, removing the slippery-conditions

pressure bias.

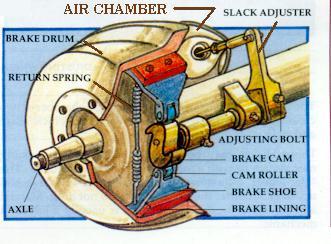

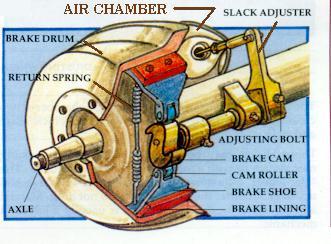

- 7. The Brake Chambers

- These are enclosed chambers which contain a

rubber diaphragm backed by a steel disc connected to the push rod

which actuates the brake in each wheel. Depressing the treadle valve

directs air into these chambers, applying the brakes - providing of

course that there is no excessive slack in the linkage. See below.

- 8. The Slack Adjusters - this is the name given to the levers which

impart rotary movement through the cam shafts to the actuator cams

inside the brake

drums, which force the brake shoes outwards against the drums.

These levers have a second function, that of providing a means of

adjusting out the slack which develops on an hourly basis as the

brakes are used.

|

|

Slack Adjustment is accomplished by means of a worm-and-pinion setup

between the lever and the camshaft - there is a bolthead provided for

adjusting the worm gear around the pinion. In high-use conditions, such as

mountain driving, they should be checked and adjusted on an hourly basis

- that's the reason for the brake-check areas found on most mountain

highways. On the other hand, flatland driving, where the brakes are

seldom used, will require less frequent adjustment. However, when in

doubt.......

- 9. The Push Rods - these serve to impart movement from the brake

chamber diaphragm to the slack adjusters. The pushrods too are

adjustable - in length. This is because, during the life of the brake

shoes, the angle of the pushrod to the slack adjuster (lever) at the

point of brake contact will change as the shoes wear. The ideal angle

of pushrod to lever is 90 degrees at this point - for the greatest

possible mechanical advantage. As the shoes wear, this angle must be

checked periodically, and adjusted as required. This is not a daily

procedure, however, and should never be confused with slack

adjustment!

- 10. Spring Brakes - There is no mechanical linkage from the driver's

position to the rear brakes. The Clippers were originally provided with

a "drive-shaft" brake, controlled by a lever and mechanical linkage

which imparts braking energy to the drive shaft. This system is not

nearly as powerful as the air-operated rear brakes; indeed it is

doubtful that it would suffice to stop the coach in the event of air

failure at speed on a good hill - and it would of course be of no value

in the event of a driveshaft failure. Enter the "Spring Brakes." These

provide parking and emergency brakes by means of exerting spring pressure

to the rear brakes, through the pushrods and slack adjuster systems

described above. They incorporate an extra "spring chamber" which is

"piggy-backed" to the regular rear brake chambers, but which contains a

very powerful spring which applies the brakes at all times, unless

defeated by a counter-operating air chamber which works against the

spring to disengage it from the system. Thus the brakes are applied at

all times, except when the spring brake chamber is pressurized. This

pressure is applied through a valve accessible from the driving position

- usually mounted on the dashboard. Until you have air pressure, the

vehicle cannot be moved - a good idea from a safety standpoint. In the

event of air pressure failure during operation, the brakes will be

applied by the springs, giving an "automatic emergency brake" aspect to

the operation.

The spring brakes may be mechanically defeated by being "caged"

mechanically - the chambers come supplied with special bolts which can

be inserted into the front of the chamber and engaged with the

diaphragm. There are nuts supplied with them as well, which may then be

tightened down, pulling the bolt and diaphragm, forward, and thus

disegaging the spring brakes. This is heavy work, and is best done when

the brakes are already caged by air pressure, ie disengaged at the dash,

but in the event of catastrophic air failure stopping the vehicle in an

embarassing place, they may be mechanically caged so that it may be

moved. in such event, be sure to block the wheels, and engage the

mechanical driveshaft brake before de-activating the spring brakes!

An additional caveat with spring brakes: NEVER attempt to dismantle

a spring brake chamber without the proper jigs and tools! There is

immense spring pressure which WILL cause you extreme damage if this

advice is not heeded! Spring Brake Chamber service is for experts only!

- 11. The Pressure Monitoring System - it will be seen by this

point that it is vital for the operator to know at all times what the

pressure of the system is. (See "know your pressure" below.) The

pressure monitoring components are:

- A. The Dash-Mounted Pressure Gauge - this provides visual indication

of the pressure of the system, and should be monitored at all times.

Thus, if for example, there is a system malfunction and the pressure is

dropping, your first indication will not be the locking up of the rear

wheels as the spring brakes apply. Exceptionally slow recovery of

pressure after brake application can give early warning of compresssor

problems, leaks, slipping drive belt, etc., so that the driver can pull

over and investigate before the situation exacerbates. If the regulator

sticks - and this can happen, especially in freezing weather - the

excessive pressure buildup will be indicated to the driver, who will

pull over and shut down so that the situation can be corrected before

disaster strikes.

- B. The Warning Light - In cases of driver inattention to the above,

the warning light, and it's companion listed next will serve to give

"last call" notice.

- C. The Warning Buzzer - this is the Very Last Call before disaster

strikes. During operation, things should never be allowed to get this

bad! - the pressure gauge should be as much a part of your "regular

checks" as oil pressure, temperature, speed, mirrors, and of course

what's happening out there in front.

- 13. The Air-Operated Switches

- The Stoplight Switch - located on the underside of the floor, just

ahead of the rear axle, this switch is plumbed into the distribution tee

which feeds the rear service brakes. When pressure is applied to the

system, the switch closes, providing power to the stop lights. Some

models have a "Stop" indicator lamp on the dash which signifies that

this switch has done its job. Some models use this switch directly to

operate the stoplights, others use it to energize a relay - mounted on

the switch itself - which provides a higher-current capability to the

stoplight circuit. See Wiring Schematic for connection details.

- The Low-Air Switch - This normally-closed switch is opened when

the Air Pressure reaches the 60 psi range - that at which the brake

system may be depended upon to operate. It is connected to the Low Air

Light and the Low Air buzzer. A spring-loaded Defeat Switch is usually

wired into the circuit, which may be held down at startup until the

pressure builds up, to silence the buzzer. If you have to hold the

switch down for more than 90 seconds, your system has problems and

should be investigated.

- Stoplight Indicator Switch - Some models had a second stoplight

switch mounted at the front, which closed when the system was pressured

up to operate the "stoplight" indicator on the dash. Or to tell the

driver that he had the brake pedal down. The use of such an indicator

light is not clear to your writer - this is no positive indication that

your stoplights are actually operating. One speculation is that, in the

early days of the Clippers, the exceptional power of the air brakes

required that the driver be aware of the possibility of surprising

following vehicles, and the dash "Stop" light was a way of reminding

him. Or her.

All of the above components of your Air Brake System should be checked

regularly, and maintained in tip-top condition.

Hit your browser's "back" button to return to the index