Would you like to make this site your homepage? It's fast and easy...

Yes, Please make this my home page!

The Flxible Clipper Handbook

- by Pete Snidal (C)2004

Maintaining Your Air Brake System

Operation of each of the components of the Air Brake must be monitored

at all times. In addition, a "Pre-Trip Inspection" should be carried

out before every movement of your coach. This will check the operation

and security of each of the elements in the system.

1. The Compressor

Air brake compressors function efficiently year in and year out for a

long time between required servicings. Thus it is easy to take them for

granted, but parts do wear, and their operation will degrade over time.

The best way to monitor their performance is simply by observing how

long they take to build up air when the vehicle is started with the air

depleted. This is also the time to check the operation of the Air

Pressure Regulator - does it "cut out" at the proper high limit, and

"cut in" at the proper low one? Here's the procedure:

Upon starting the engine, the driver makes a note of the position of

the second hand of his watch - or begins counting, and notes the time it

takes for the air to build up to a certain value - the end of the

gauge's "red zone," is a good one. The air pressure of

the system, assuming it's starting at Zero, must reach the end of the

"red" zone of the gauge - 80 psi - within 90 seconds. It must continue

to build to 120 psi, according to BC DOT regulations, within 3 minutes.

At this point - and this is important! - it must STOP building pressure

- ie, the regulator must deactivate the compressor and the gauge will be

seen to stop climbing. If it continues to climb, there is a fault in

the regulator, and the engine must be shut down and the condition must

be checked.

Once it has been established that the compressor is building air within

the required time limit, and that the regulator is "cutting out" at the

required pressure, the DOT-mandated Pre-Trip Check requires that the

operator then reduce the air pressure by "fanning" the brake pedal

repeatedly until the low limit is reached, and ensuring that the

regulator "cuts in" at that pressure. With the Flxi's, it should cut in

- ie, the gauge should begin once more to climb - at the top of the

"red zone" - the 80 psi lower limit. Once again, the max pressure of

120 psi must be attained in a reasonable time period - within 2 minutes

- and the compressor must once again "cut out."

During the period of brake fanning to reduce pressure, you should also

observe just how much of a pressure drop you get for each application of

the brakes. How hard the application is should make little difference -

the air chambers fill with a 1/2" brake pedal movement just as much as

when it's floored. (This should NEVER be done when the spring brakes are

applied, by the way - more on this later.) A drop of about 5 psi per

brake application is normal. Much more than this is a sign of possible

leakage of a line or air chamber. If this occurs, the operator should

have a helper apply some brake while he listens at each wheel and under

the bus in general for the sound of any escaping air.

Once the compressor and its regulator have been checked and approved in

this fashion, we may proceed with the rest of the system.

2. Reservoirs, Lines, And Brake Chambers

The engine should then be shut down, and a "walk-around" should be done

to listen for any signs of escaping air. It is a good idea to have a

helper apply brake as well - 1/2-3/4" of brake pedal is enough - while

you listen for any sign of air escaping from an air chamber. Of course,

if any air leak is detected, it must be investigated and repaired.

Leaks may be checked for with soapy water applied with a brush to

suspected joints and lines. Air escaping within a brake chamber

indicates a leaking diaphragm, and this condition must be remedied

before operating the vehicle. Exchange brake chambers are not expensive.

If replacing a (double) (rear) Spring Brake chamber, remember NEVER to

attempt to dismantle the chamber!

3. The Brake Slack

Now for the slack adjusters - these must be checked before every trip,

and of course adjusted if necessary.

Before checking any brake adjusters, ALWAYS first ensure that the bus

cannot roll over you - you'll be lying down very close to a wheel in

every case. The spring brakes will have to be disengaged, since all

slack is of course taken up when they're on. This means you'll have to

block at least one wheel - fore AND aft! - even if on level ground - and

more if on a slope, before disengaging the spring brakes. If you still

have a driveshaft brake as well, it won't hurt to engage it, but it's

not a good idea to count on this as your only safety, especially if it

hasn't been tested recently. (It may be tested by attempting to move the

bus with the handbrake set, and no blocks at wheels.)

Once the safety considerations have been met, it's time to check the

slack at each adjuster. Truck supply houses sell a "Brake Buddy" (TM) -

a special wrench with a fitting to allow it to be used as a lever on the

slack adjuster. These are a handy thing to have in the tool box - with

your tire pressure gauge and tire beater. If you don't have one,

you'll have to move the slack adjuster some other way, but the object in

any case is to move the slack adjuster at the pushrod end back and

forth, checking the distance it moves at this point.

The slack should be set to 1/4." If it moves more than 1", it must be

tightened. This is accomplished by rotating the adjuster worm, by means

of the adjuster bolt, about the pinion gear until all slack is taken up,

then backing off on the bolt until there is 1/4" of free play.

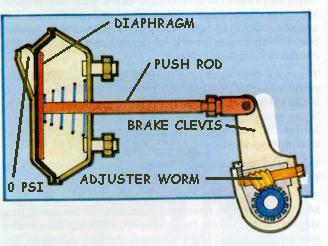

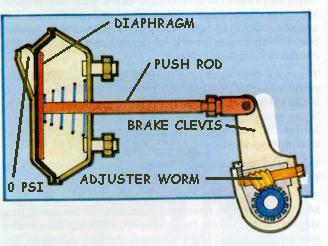

Brake Off. The only way to tell

if this brake is sufficiently tight is physically to move the slack

adjuster lever until movement is stopped by contact of the shoes against

the inside of the brake drum. As movement approaches 1", adjustment is

indicated. |

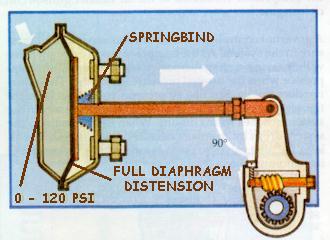

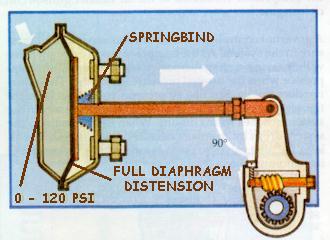

The Slack Adjusters and Brake Chambers At Their Limits Of

Movement. |

Brake Full On. This brake is too

slack - it should NEVER be possible for the diaphragm to reach full distension.

Spring bind in the return spring prevents any pressure from being

exerted against the brake shoes. Furthermore, even if the brake is

operating at this point, there is no "wiggle room" for brake wear or

fade. |

Danger Alert! - Reversing Adjustment!

NEVER count on simply tightening up the adjuster bolt, and then moving

it back a half-turn! It is possible that an adjuster has been installed

in such a way that clockwise "tightening" of the adjuster bolt may in

fact be LOOSENING! Hence, the misguided operator may be taking the

adjuster to Full Loose, then tightening a half-turn, which is obviously

a waste of time and a huge danger! Some slack adjusters may be fitted

upside down or inside-out, and this condition will then attain.

The slack MUST ALWAYS be re-checked after adjustment by physical movement

of the slack adjuster and pushrod. A further check may also be useful:

if you have an assistant make a light brake application while you

observe the action at each brake, you should see only 1/4" of movement

of the pushrod and adjuster end after adjustment. If this method is used

as a pre-adjustment check, be sure to re-adjust (and re-check!) if

observed movement is approaching 1".

4. The Push Rods

The brake chambers exert the greatest mechanical advantage against the

slack adjuster levers when the angle between the pushrod and the lever

is 90 degrees. Consequently, when new brake shoes are fitted, the

pushrod length is adjusted so that this angle will be just a bit over

90, and as the shoes wear (this wear of course being compensated

for on a daily basis by slack adjustment), the angle at the point of

contact will become a bit short of 90. This compromise must be

readjusted so that the angle at full brake application is as close to 90

degrees as possible. This is accomplished by physically changing the

length of the pushrod with the adjustment provided. This is not a daily

procedure, but it should be monitored and corrected as necessary.

Spring Brake Adjustment

Since the Spring Brakes are an integral part of the rear brake chambers,

when the rear brakes are adjusted, so are the spring brakes. ie, they

require no further or special adjustment.

Monitoring Brake Shoe Wear

Brake shoe wear should also be monitored. Most vehicles require

periodic removel of the wheels and brake drums so that the shoes

and drum surface may be inspected for wear, and this is a good idea with

the Flxible Clipper brakes as well. However, on most models, the brake

drums are open enough so that the shoe thickness may be monitored to

some extent. The thickness of the brake lining riveted to the brake

shoes should not be allowed to reach less than 3/16". If lining this

thin is detected, proceed directly to a reliable truck brake repair

facility for lining replacement. Have the front wheel bearings repacked

at the same time, of course, and the drums inspected carefully for

excessive wear, cracking, or any other defects. Do not rely on

difficulty with brake adjustment to tell you it's time to replace your

brake shoes, although this may sometimed also be a problem indicating a

need for replacement.

Hit your browser's "back" button to return to the index