Would you like to make this site your homepage? It's fast and easy...

Yes, Please make this my home page!

The Flxible Clipper Handbook

- by Pete Snidal (C)2004

Relays 101

What A Relay Is, and Why You Need It

A Relay is a sneaky way of switching short and/or heavy lines

carrying high current with thin, possibly long lines and skinny

switches carrying very low current.

|

A low-current electromagnet is used to draw down a

spring-loaded bar to complete the high-current circuit. This

allows low-current switches and long, thin wires to control

high-current devices, such as motors, light systems, etc. through

shorter and heavier-wire paths.

To wire it in, you need only identify the low-current

terminals - they will make the relay "click" when connected to

power - and the high-current terminals - they will close when

the "click" is heard from the low-current connection. A diagram is

usually supplied with the relay.

It allows you to run a really heavy (#12, say) wire from your

battery via a short path and then to "trigger" this line with a

low-current much less direct line from the "office."

|

Do You Need Any?

One of the features of our beloved Flx's is their length - the

alternator, voltage regulator and batteries are in the back of the bus,

and the light switches and front lights are 35 feet up in the front.

The current path is even longer for the rear lights and other load

devices at the rear - from the batteries up to the front panel, through

the switch, and then all the way back again to the light(s), starter

solenoid, demister motor, or whatever. This 70 feet of wire can eat up a

fair amount of power, especially at higher amperages. The taillights/rear

marker light circuit, for example. This is especially important since

today, the expectation of following drivers is higher than it

once was for lights on the rear, and for this reason, many flx owners

have added to the complement of lights showing at the rear. In many

cases, we may be going slower than much of the rest of the traffic,

and this is an additional reason for some extra lights. And of course,

extra lights just compound the problem of the voltage drop in the 70-ft

circuit. Adding a relay can reduce the length to a matter of the width

of the bus, rather than the length.

A second feature of our busses is their age - the wires in there aren't

getting any younger, nor are the connections and joints along the way.

But this current path is almost certainly adequate for the low draw

required to energize a relay. Thus, for example, the 10 Amps or more

required for the rear tail and marker lights can be carried by a short,

fat current path directly from battery through relay to lights, and the

much lower current required to energize the lights will easily be

carried by the existing light circuit - ending now at the relay, instead

of at the individual lights. Similarly, a relay may be used in case of

difficulties with the starter solenoid - itself another, larger relay -

or accessories such as a radiator mister pump.

Testing: Will A Relay Help?

A relay is only necessary in cases in which the standard wiring is overtaxed.

To test whether this applies to your application, it is useful to do a

Voltage Drop Test.

In this test, you look for a small voltage where there shouldn't be one -

between the battery "hot" terminal (the one not grounded to the chassis)

and the load device feed wire, as close to the device as possible.

When the switch is open, there should be full battery voltage between

the battery and the device, - ie across the switch - and when the switch

is closed, this voltage should fall to 0. If any voltage is indicated,

this "drop" signifies that power is being wasted in the circuit from

battery to load.

For example, let's check for voltage drop on our example, the rear

lights. First, locate the terminal on the rear board which feeds them.

This should be terminal 17 - you can check simply by finding the

terminal which is "hot" when the marker/tail lamps are on, and isn't

when they're off.

Let's look at the current path for this circuit. The power must travel

from the batteries to (most likely) the terminal on the starter solenoid -

to the hi-current (#6 Cable) terminal (probably 13) on the rear board,

up the cable to the busbar (behind the switch panel), through the

"Mark-Taillamp" switch, and back down to the rear terminal board 17,

before it is distributed to the tail and marker lights. That this

70-foot path may be showing some resistance, meaning lights dimmer than

necessary, should come as no surprise. To see just how bad the

situation is, just set your multimeter to Low DC Volts (0-5 is good),

and check the voltage between the "hot" starter solenoid terminal - or

the Big Amps rearboard terminal 13 - and the taillight terminal (13).

With the switch off, the voltage should read full battery voltage, since

there is so little current draw by the DC Voltmeter. But with the lights

on, there should be no voltage showing, ie no "voltage drop." If there

is (and I'd be surprised if there isn't!), this can be corrected by

"jumping" the two terminals together (which would result, of course, in

the voltmeter reading dropping to 0). If this results in considerable

brightening of your lights, you know that fitting a relay will be a big

help!

(The purists among us might insist that, in an ideal world, there should

be NO voltage drop in the 70-ft circuit, and that A Real Man would just

correct the problems - by cleaning/replacing all terminal connectors,

switches, and possibly conductor wires. Possibly true, but it's also

possible that you still wouldn't completely eliminate the drop,

and in any event, the relay solution is much simpler.

Doing The Job

First, ensure that you have the necessary parts:

Tools and Materials

- A Relay - Your local auto supply store will have a selection

of small horn relays. Bosch make a nice one.

- Wire. Pick up a roll of #14 stranded automotive wire. Get it

in red for (-) ground systems, black for (+) ground.

- Crimp connectors - some spades, for the relay, and a ring or

two, for the battery.

- Crimping tool for the connectors

- The usual tools - screwdriver, pliers, wire strippers

Once the materials are on hand, it's just a matter of following these

steps:

IMPORTANT! - First disconnect your battery from the system to

avoid unpleasant surprises such as fire, etc when working with the

connections.

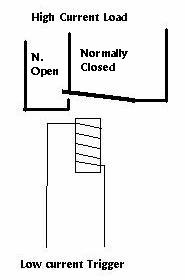

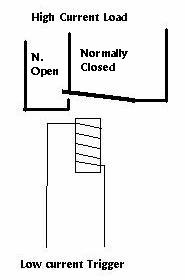

- 1. Referring to the diagram etched on the relay case, determine

which terminals do what. Two terminals will be the low-current'

"energizer" terminals, and two the high-current "load" ones. The

drawing at the top of this page may help. If there's no diagram, you can

use this strategy.

- 2. This would be a good time to attach spade terminals to a pair

of wires for the high-current circuit. Cut two pieces of fresh #14

wire long enough to reach between the intended mounting point and the

terminal board.

- 3. Strip each end of each piece, and attach a female spade

to one end, and a ring terminal to the other end of one of them. Attach

the other one to the fuse holder, and leave the other end of the fuse

holder alone for the time being.

- 4. Now for the energizer circuit. Using a different colour wire,

#16 is fine - prepare two more pieces by stripping their ends, and

attach female spade terminals to one end, ring terminals to the other.

- 5. Referring to the diagram on the relay case, clip the wires to

the appropriate terminals

- 6. Mount the relay close to the rear terminal board. Ground one

of the energizer terminals by fastening its ring connector under the

head of the screw which mounts the relay to the body sheet metal.

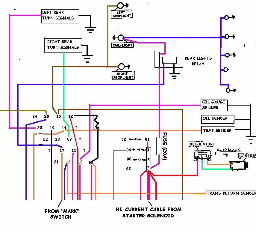

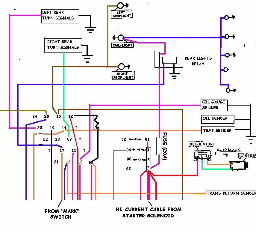

The Rear Circuit Board, Showing Rear Light Relay - Click to Enlarge

|

- 7. Disconnect the taillight feed wire from the board. This should

be terminal 17 - it's the one that goes "hot" with the rear lights on.

- 8. Using a butt connector (or, better still, shrink tube and

solder) connect one of the relay's hi-current wires to the taillight

wire - the one that came off of terminal 17.

If length permits, just strip the taillight wire, crimp on a spade

terminal, and attach it directly to the relay's other hi-output

terminal.

- 9. Connect the other low-current energizer terminal wire to the

rear board terminal which previously fed the taillights. (probably 17).

This will provide current to energize the relay from the MARK switch in

the cockpit.

|

- 10. Finally, connect the remaining relay hi-current terminal wire

- the input - through a fuse to the rearboard terminal 13 - the one with

the fat wire coming from the starter solenoid. (Hi-current feed.)

- 12. Re-connect the batteries and test your rear lights. In the

event of non-performance, check using the list below

Trouble-Shooting List

If, after all this, you find you no longer have rear lights, it's time

to do a systematic check of connections. Here are some suggestions:

- 1. Power input to relay: Check at the input line fuse for power

to ground.

- 2. Power output from relay to lights: use a temporary jumper to

jump across the relay terminals from in to out. If this lights the

lights, you know that the relay is faulty, or that it is not closing

with power from the light switch.

- 3. Relay function. First, jump from a hot line

(such as the new fuse input) to the relay trigger line - terminal 17

on the rear board as shown in the diagram. This should produce an

audible click as the relay closes. If you hear the click, have someone

check for taillights.

- 4. Power from light switch to relay trigger terminal. Check for

power at relay trigger terminal with light switch on.

- 5. Relay trigger ground connection. If all above works, jump

from a good ground to the trigger ground relay terminal.

Other Uses For Relays

In the same way, relays may be used for other purposes at the far

reaches of your bus. For example, if you're using a radiator mister

system, with a rear-mounted pump, you can wire yet another relay in

the same fashion as described above. Thus, you'll require less current

capacity for your trigger line.

Another use for a relay is to eliminate high-resistance problems in the

starter trigger circuit - if you sometimes have to go back there and

trigger the solenoid by hand, you can wire a relay to fire the solenoid

- a relay for a relay, so to speak.

No Connection Diagram?

There is often a little teensy diagram on the relay itself, but your

mileage may vary. If you have no diagram, you can still use the

following coping strategy to determine connections:

There will be 5 connections: Two for the energizer circuit, and

three for the main circuit - one common, or "input", and two "output," -

one "normally closed," and one "normally open." We will use the

"normally open" pair, meaning that it closes when the relay is energized

by power from the light switch.

- First, find the energizer circuit. Which two?

We will use a "hot" wire from the battery, and a ground wire.

Clip a jumper to each battery terminal. Attach the ground

clip to any tab on the relay.

- Try a hot wire to each of the others in turn, looking for a "click."

- If you don't get a "click," move the ground clip to the

next one. Repeat step 2. Keep doing this until you identify

a pair which will make the click. (Close the relay) Polarity

doesn't matter; either of these two may be grounded or made "hot"

to energize the relay. Mark them.

- You now have 3 terminals left. One of these is a

"feed," or input terminal, and the other two are "load," or outputs.

We will only have to identify two of these remaining terminals - those

which are connected when the relay is energized.

-

First, energize the relay by connecting the battery to the energizer

terminals. then, using your multimeter on "ohms," find the two that

are connected when the relay is energized. These are your new "high

beam switch," or "Load" terminals. Mark them. Disconnect the energizer

power, and check to make sure that they are now open.

How To Connect It

Hit your browser's back button to return to previous page