|

|

|

The only difficulty with this scheme is actuation - how can the air-operated rear brakes be applied in the event of loss of air pressure (emergency) or for parking, when the air supply eventually depletes due to the air compressor being shut down with the engine (parking)?

Enter the Spring Brake. These utilize a second system of brake actuation - only for the rear brakes - being applied by very strong springs, which duplicate the action of the otherwise air-operated brake chambers, by the addition of "Spring Chambers," which are "piggy-backed" onto the former. This system, although not originally supplied on the Flx Clippers, is a far superior and much safer one, and thankfully may fairly easily be retrofitted to the Clippers. The job is in fact only a few hours' work, and requires less than $200.00 worth of parts and pieces. And, best of all, you can leave your original driveshaft brake in place for extra backup!

|

|

If your chambers are still single, you should have a knowledgeable shop or mechanic install spring brakes on your rig. If you're not already confident in your competence to do this job, do not consider this article a "how-to." Rather, it is intended to acquaint you with what is involved with the job.

First, let's look at Spring Brakes in detail. Following is an excerpt

from an earlier article on Air Brakes in general:

(Danger Note! -

Spring brake chambers, obviously, have big, heavy springs in them.

Attempting to dismantle them without proper information and precautions

will earn you a Darwin Award!

This kind of parking brake has a major difference over the brakes we'

re all used to - if the system loses its pressure, the de-application

pressure is also lost, and the parking brakes will come on as the

pressure decreases - providing an "automatic" setting of the parking

brakes if system pressure is lost on the road. This is another reason

we must pay attention to system pressure - if it drops to the danger

level, you need to pull over in the first safe place, while you still

have enough air to maintain control over your brakes, or you just may

find yourself stopped in the middle of the freeway!

And don't ever forget, the rear brake slack must be done with

the brake springs caged! - So you'll have to chock your wheels and

set your brake control to the "off" position.

First, the Caveats. A little discussion of what could go wrong:

Assuming that didn't happen (thank gods), you're still stuck with your

emergency lights flashing, in the middle of the lane. You've got to get

your coach out of the way as soon as possible, meanwhile first setting

out flares and directing traffic around this obstruction you've created.

(With luck, you've got some crew aboard to help with some of this.)

Your brakes can be released, fortunately, by using your "caging bolts" to

withdraw

the brake springs. It means getting out and under, and some sweaty work

with a big wrench for 10 or 15 minutes. Hopefully, you've set blocks

under your wheels, and set your old parking brake (if it's still there),

so your bus doesn't roll over you when you get the brakes off, and you

can then close your parking brake valve - to eliminate any more air loss

- and drive to somewhere where you can diagnose and repair the problem

sans your parking/emergency spring brake. (Which is hopefully backed up

by your still-there driveshaft brake. Belt and suspenders.)

Either of these scenarios assumes the main possible problem with your

installation - that of air loss from your new line letting go. So we see

right away that this new airline - from take-off point through control

valve to brake chambers - as with all brake components - MUST be reliable

and totally secure!

Other possible problems could develop from faulty installation of the

new brake chambers themselves - failure to tighten the mounting bolts

properly, install safety cotter pins in the linkage clevises, or

possibly failure to adjust the rear brakes properly after installation -

remember, your rear brake adjustment must now be done with the brake

springs caged by air pressure or bolt installation!

However, whether you decide to do the job yourself, or "farm it out,"

here are the steps involved:

Tubing may be of soft (semi-rigid) copper, or plastic. For air work of

any kind, always ensure that you are using the proper schedule (a rating

of pressure and quality) for the job at hand. Different grade tubing is

used for aquariums and Pepsi-Cola dispensers than for Air Brakes!

There is a special type of compression fitting for hi-grade plastic

tubing, approved for airbrake use, which uses a special insert which

is slipped inside the tube before the nut is screwed to the fitting.

This reinforces the end of the plastic tube sufficiently for a solid

compression joint to be made.

Often, the compression bushing forces its way into the tubing, so

although the joint may be connected and reconnected repeatedly, bushings

should not be reused for other connections. New bushings should be used

each time, and the tubing recut to a fresh surface.

The next step is to remove the first of your existing brake chambers.

Before you do this, check that the existing pushrod length is correct.

To do this, use a Brake Buddy(TM) or other suitable tool to move the

slack adjuster to full brake position. Check the angle between the

pushrod and the slack adjuster lever at this point. If the angle has

gone to less than 90 degrees (this is a natural occurence due to brake

shoe wear), you'll want to lengthen the pushrod by adjusting the

position of the clevis - ie, make your new pushrod just a bit longer.

Remember this for when you set the length of your new pushrod. Then,

locate the clevis pin at the outer end of the slack adjuster. Remove the

cotter key from the end of the pin, and then remove the pin. Now you're ready

to detach the air line between the chamber and the distribution tee -

look for the swivel fitting and unscrew this first. (One end will likely

be a "swivel" fitting, and the other will be a pipe fitting that

requires twisting the whole line to move.) Then you can unscrew

the two big nuts that hold the brake pot onto the bracket welded to the

rear axle, - these are fun; one of those 1/8 turn at a time

propositions. Once you get them off, you'll be able to lift the pot free

of the axle. Now for some bench work.

Once you've got the first brake chamber on the bench, you can use it to

determine where to cut the pushrod supplied with the first of your new

double-pot chambers. - They come in a universal length, to be cut for

the particular application of the new owner.

First, measure the distance from the mounting face of your old pot to

the center of the clevis pin holes. Make a note of this distance - the

target is to cut the pushrod on the new double pot, and to reinstall the

clevis so the distance is the same.

Now, examine one of your new double pots. There is an air chamber at the

rear, just as with your old one, but there is an additional air chamber

"piggy-backed" to this one. The latter chamber contains a very strong

and highly compressed spring - DO NOT EVER under any circumstances

contemplate removing the retaining ring which holds this spring chamber

together. This WOULD result in heavy damage to your person! - that

spring is under STRONG tension! Disassembling Spring Brake Chambers

without the proper tools, fits in with taking hammers to old TV tubes as

a qualifier for the Darwin Award.

And soon it will be under even more tension, since the spring brake must

be de-activated before we continue with the installation. This will

mean using the cage bolt to hold the spring tensioned, once we get it

that way. There are two ways of tensioning the spring. The first is

just to fit the cage bolt into the end of the chamber - it will rotate

and lock into place inside the spring retainer - and use a suitable

wrench to tighten the bolt, drawing the spring up against the end of the

chamber. This starts out to be a fairly easy chore, but as the spring

tension increases, the torque required increases substantially - the nut

will actually get quite hot, as will you yourself. It can be quite a

workout.

Or you can use shop air pressure, if you have it available, to do the

work for you - this is easier on the nut and threads, and much easier on

your arm. Chuck the air chamber securely in your bench vise, and remove

the protective plug in the spring air chamber air fitting. Then fit your

blow gun into the air fitting, and apply air pressure. This will force

the spring up against the end of the chamber, releasing tension on the

bolt. This will allow you to run the nut down the threads with much

less effort - you'll need 30-40 psi to pull the spring completely back.

DO NOT get your fingers between the nut and washer, or washer and

chamber - if the blow gun slips out of the fitting, spring pressure will

suddenly return with a vengeance!

Once you have the spring completely caged, the service brake chamber

will operate just as did your old one, and you may continue with the

installation. First, returning to the original air chamber, loosen off

the locknut and unscrew the clevis. Now, you'll want to cut the new

pushrod so that you can screw on the old locknut and clevis to attain the

same effective length (mounting flange to clevis length) as your old one.

(This is the time to adjust the length for that 90 degree angle if

necessary!)

Do the measurements and then make the cut - with hacksaw or Skilsaw and

cutoff disk - and screw on the locknut and the clevis - you may have to

dress the end of the pushrod with a fine file, depending on how violent

the cutting process was. Be sure to tighten the locknut securely

against the clevis.

This done, you'll be able to mount your new dual brakepot in place

of your old one. Remove the new mounting nuts, and introduce the new

chamber to the flange on your rear axle. Re-fit the clevis pin while you

can still move the chamber around on the flange, and then fit the

lockwashers and mounting nuts. Snug them up, and then, using your brake

buddy or similar tool, pull the slack adjuster against the brakes, and

check that the angle between pushrod and slack adjuster at this point of

application is a bit more than 90 degrees. If it is less than 90, you'll

have to adjust the pushrod length by means of the clevis until it is

less than 90 - as the brakes wear, this angle will increase past the

ideal 90 degrees until it is more, and you'll have to adjust it

again. Thankfully, this is not a daily chore, like adjusting the slack

adjuster. Once you've got the angle right, (no pun intended) be sure to

secure the clevis pin with a new cotter key. Ensure that the pot

mounting nuts are now tightened securely.

Now, adjust the slack adjuster for 1/4" or a bit less of free play - meaning

so that you can move the end of the adjuster only this much before the

movement is stopped by the shoes butting against the inside of the brake drum.

This adjustment is done by rotating the 9/16" bolt head which rotates

the worm in the slack adjuster lever. Tighten the bolt until you can get

no movement, then back it off until you can move the pushrod about 1/4".

You may now re-fit the service brake air line to your new service brake

chamber. You will likely need a new fitting or two - a 45 degree

will likely be required to re-orient the line for the new fitting

position on the air chamber. Use high-quality brass fittings, obtainable

at the truck supply house where you got the air chambers and air lines.

Resist any temptation to use anything but the highest-quality fittings

suitable for airbrake use. If in doubt, ask the parts man! Be sure to

route all brake hoses so that they won't be able to snag on any objects

projecting from the roadway.

This done, repeat for the other side. Once the brakes are re-connected,

you have as much brakes as you did before, with a pair of new,

still-caged spring pots which give you the potential to continue with

spring brake installation. All that's left to do is to provide for a

driver-controlled air supply to the spring brake chambers, and to air

them up and remove the caging bolts.

Now, to provide air supply to the tee. First, decide on your routing

for the air line from tee to the valve position at the driving position.

DO NOT even contemplete running the line below any cross-members - if

this line catches on any obstructions and tears out, your rear wheels

will lock up immediately! You'll likely have to drill a hole in each

cross-member for your new line. Obtain the proper fittings to adapt

from the thread type of your tee to the fitting type of your chosen line

- you can use soft copper of the proper schedule (thickness and psi

rating) as was used on your original air system, but you'll likely chose

the modern air-brake approved plastic line and matching

ferrule-and-filler end fittings. You'll likely need adapter fittings

from this type of fitting to the threads of your tee, and to those of

your control valve at the driver end. (See earlier discussion of types

of threads and fittings.) I used 3/8" line; this is a minumum size; you

may chose to use 1/2". (Remember a high-capacity, reliable air supply is

essential to safe operation of your coach with spring brakes.)

When you purchase your line, be sure also to buy rubber grommets to

mount where the line goes through the cross-members, or any other metal

parts of the coach. This is to inhibit chafing of the plastic, another

possible cause of catastrophic unwanted brake application. The grommets

will tell you what size to drill your holes.

Once the holes are drilled, route the line from the tee to the driving

position - you'll likely want to mount your control valve on the

dashboard.

This last one can be perplexing. The original Flxible air system, using

semi-rigid copper tubing, presents a number of problems to break into a

place such as the supply to the treadle valve, or even the air horn

button on the floor. After some investigation, your writer chose the

supply to the air pressure gauge. This is not a high-volume connection,

since the air gauge supply is only 1/4" line. However, my reasoning is

that connecting into the air gauge supply close to the gauge means that

any leakage from the new tee downstream to the springbrake pots will

show in the gauge quickly, and I'll just have to monitor and be ready

for it. So I put a tee in the back of the pressure gauge, and connected

the existing line to one side, and the input to my springbrake valve on

the other. The line from the springbrake valve to the distribution tee

at the rear axle is 3/8".

Once everything was connected, I started the engine, and when pressure

was up to snuff, opened the springbrake control valve. This pressurized

the springbrake chambers, taking the pressure off the caging bolts,

which I was then able to remove as finger-tight. Releasing the valve, of

course, sets the brakes.

This type of installation would require the addition and mounting of the

separate air tank and relay valve, and tapping into the system in the

region of the reservoir feed - or just after the dry tank. This means

complications dealing with the semi-rigid copper supply lines, and I

preferred to leave well enough alone.

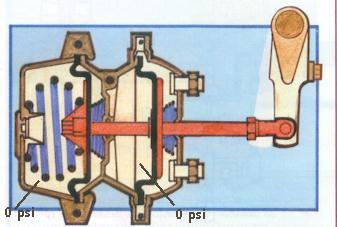

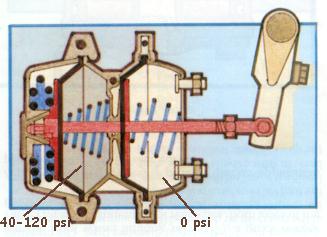

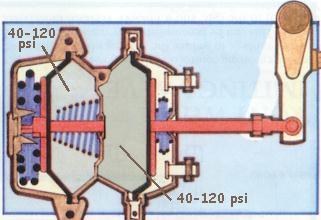

Spring Brakes - Parking Brakes for Air-Equipped Vehicles

Since it would be ridiculous to expect an air

chamber to maintain pressure over long periods of parking, the

spring brake has just that - a spring applies the rear brakes,

which are therefore always on, unless the spring is "caged" by a

second additional air chamber, "piggy-backed" onto the one already

there for the regular service brakes. To de-apply the parking brakes,

the system must first be brought up to pressure (the compressor) and

then the spring chambers are charged with air by means of the

dash-mounted parking brake valve. This offsets the springs and

lets the vehicle move. (In most cases, there is also a mechanical

means to cage the springs in case of emergencies - you get out and

under, remove the dust cap, and screw the cage bolts up by hand.)

Important Safety Note!

Does this mean that you will always have an automatic emergency

brake, which will come on every time you lose pressure? No, there is

still one eventuality which will not - ever - be accounted for, and that

is excessive adjuster slack! The final determinant in the

airbrake equation is always the mechanical linkage between the

air chamber/brake pot and the actuation lever - the slack adjuster. If

any adjuster - or all of them - is too slack, no amount of spring or air

pressure is going to put that brake on - the push rod will move to its

full extent, and 20,000 Lbs of coach will sail blithely on into whatever

disaster awaits. NEVER let your adjusters get too slack! Check them

daily, and more than that when you're using your brakes more than usual.

Expertise

Since this is a vital part of the safety considerations for operating

your coach, a certain level of mechanical expertise is required, and

certain standards must be maintained during this installation. If in

doubt, enlist the services of a certified mechanic, or take your Clipper

to a reputable shop to have the installation done. Still, it may be a

help to read on, if for no other reason, just to understand what will be

involved in the procedure.

1. Sudden release of spring brake pressure

Imagine driving along on the highway, traffic behind you fairly heavy,

and perhaps following a little too close, when suddenly, without

warning, _your_rear_brakes_lock_up! The possiblities for bad craziness

are manifold. First, you may be involved in being the star player in a

rear-end collision - or even a multi-car pileup! You can imagine the

repurcussions when the insurers discover that your homemade band-aid and

clothespins spring brake conversion let go!

2. Development Of A Sudden Air Leak

With this one, your low air light and buzzer suddenly come on - or,

better yet, you noticed your pressure gauge dropping very fast and

without warning, or maybe (unlikely) you even heard some air hissing and

then looked at the gauge. This may have been the result of your

retrofitted spring brake system leaking air somewhere between the

take-off point (from your existing system) and the brake chambers,

or it could be from some other cause. In any event,

you're losing air pressure, and this means you have to get that puppy

over to the side of the road before the brake springs take over due to

lack of sufficient air pressure in the de-application chambers. About

40 psi is where it starts to happen. This scenario is not nearly as

scary as the first, depending of course on how rapidly the air is

escaping, and how soon you became aware of the problem, but it can still

give cause for wishing your new plumbing had been made a lot more

secure.

Doing The Retrofit

First, you'll need to assemble the necessary parts and pieces. Main

ones are:

A Word On Pipe And Line Fittings

There are a number of types and standards of what most people just refer

to as "pipe fittings." They vary in how they seal, thread pitch and

diameter, and purpose. The different main types are not

interchangeable, and MUST not be confused with one another. To go from

one type to another requires adapter fittings in between. (eg, pipe

thread to tubing flare.) The basic types you will encounter are:

To reiterate, adapter fittings must be used to connect joining

methods of different kinds together. Thus a NPT (National Pipe Thread)

Tee may be connected to plastic or soft copper tubing, providing a

fitting is used which is NPT on the tee end, and Compression or Flare

on the other (depending on what you decide to use on the tubing.)

Doing The Retrofit

1. The New Brake Chambers

First, secure your new brake chambers. You'll want series 30 dual

spring and service brake chambers. The "30" is the size - refers to the

area of the diaphragm. Fortunately, the bolt patterns for mounting are

standard. The push rod length varies, but your new universal-fit

chambes will have pushrods that are too long, and threaded for their

entire length, so you'll be able to cut them down to fit. They may be

ordered at any truck parts outlet. If in doubt, take one of your old

ones in so the counterman can get any dimensions he may need.

2. The Air Supply

A. The Distribution Tee And Air Lines

Now, you'll want to mount your new air supply tee on the cross member

just ahead of the rear axle. Mount the tee beside the existing one for

supply air. Fit the pipe thread-air hose flare adapters, angle fittings,

and your new flexible air hoses as required, connecting the air chamber

fittings to the tee. This tee may be a standard 1/2" pipe tee, with a

mounting bracket brazed to it, or your parts supplier may be able to

come up with something more exotic. Just get a size that will allow

direct fitting of your brake hoses. You'll likely need an adapter for

the air line from up front.

B. The Control Valve

There are a number of possiblities for control valves. See your local

supplier for options, and choose the kind of valve you want - of course,

you'll be using one designed specifically for the purpose. The

other consideration is where to mount it - generally on the dash, and

from where you'll be drawing the air supply to feed it.

Possible Problems With This Installation

The Anal-Retentive among us, of course, will have issues with this

installation, feeling that the possibility of unwanted sudden air loss is not

sufficiently provided for, due to the size of the feed. So let's start

our considerations with the full belt-and-suspenders possibility: the

separate springbrake air tank.

Separate Tank

To be more sure of lots of air supply - to cover the eventuality of a

diaphragm or fitting leak, for example, some installations use a

separate springbrake air reservoir, fed by the regular system through a

one-way (check) valve. This tank is located as close as practical to

the springbrake pots, and connected with large-diameter tubing - ie, 1/2"

- the same size as the flex hoses - fed by a relay valve - a

special valve which connects the chambers and tank more directly, and

is itself controlled by a second circuit from the driving position.

Once the relay valve is opened, charging the springbrake chambers, the

springbrake feed becomes a closed system, and will be unaffected by even

total loss of airpressure in the main system. The brakes will be uncaged

only when the relay valve is opened.

Second Possibility: Larger Supply Capacity

The second possibility for improvement of my system would be a larger-capacity

feed line to the distribution tee. Once again, this would require opening up

the semi-rigid copper feed line to the treadle valve. It could be done,

introducing a compression tee in this line, but I chose not to disturb

the existing service brake system. I am concluding that, if no leaks

develop downstream of the tee into the air gauge line, there will be no

problem, and if a leak does develop, it will show as a serious drop in

pressure indicated by the gauge.

---------

But Not Always...

That is, provided the deapplication pressure is provided from the

reservoir of the regular system. In some cases, the de-application

pressure is provided from a second special reservoir, supplied from the

first one through a one-way check valve, so that pressure loss in the

main system will not affect the pressure in the spring brake reservoir.

In this case, the spring brakes will only be applied when the dash-

mounted valve is operated to exhaust the air from the spring brake

chambers. This eliminates the "automatic" aspect of spring brake

application in the case of loss of pressure in the service brake

system, but allows greater operator control in that the second

reservoir can allow the operator to de-apply the brakes for such

things as small movements once the spring brakes

have brought the vehicle to a stop.